|

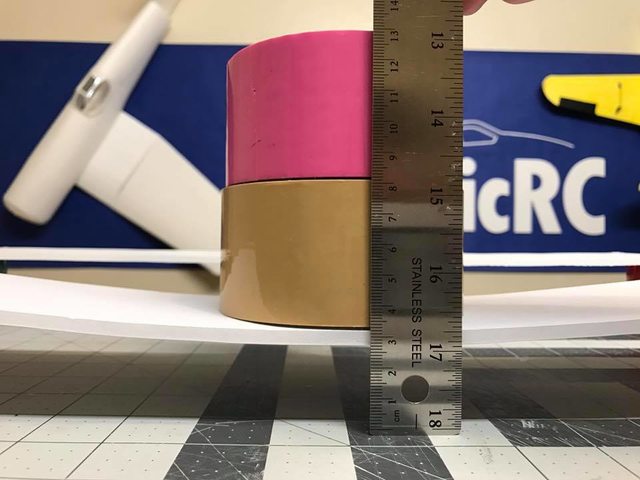

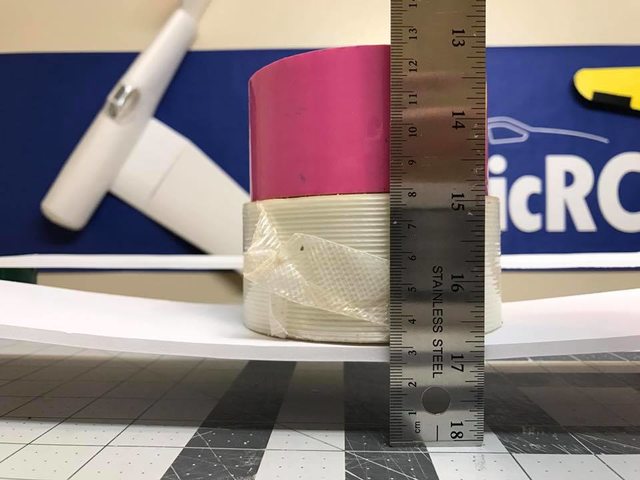

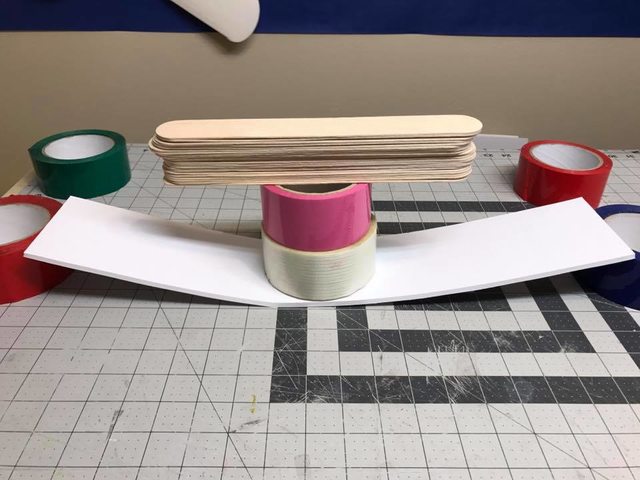

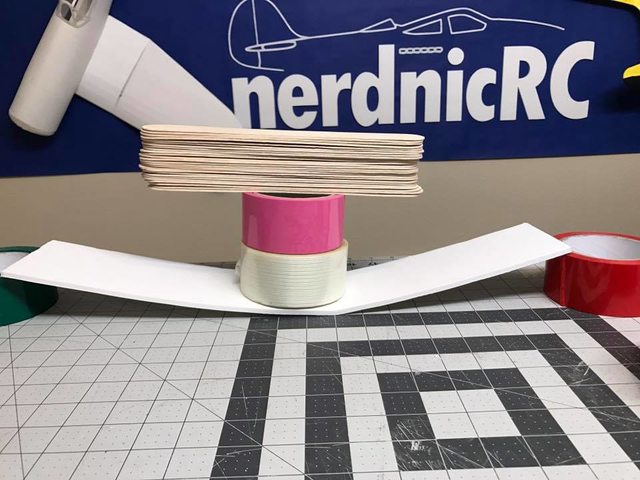

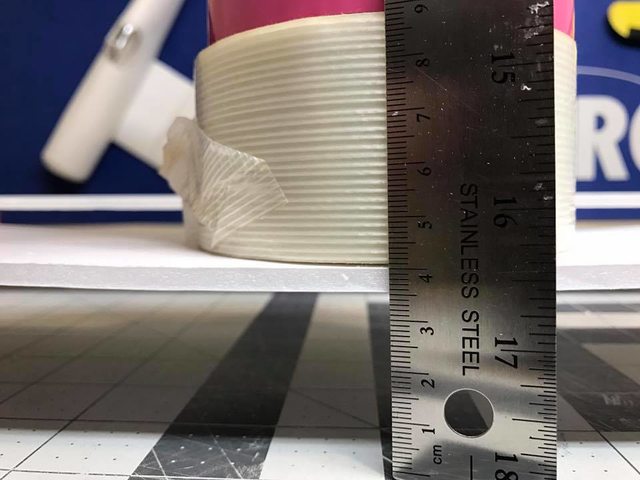

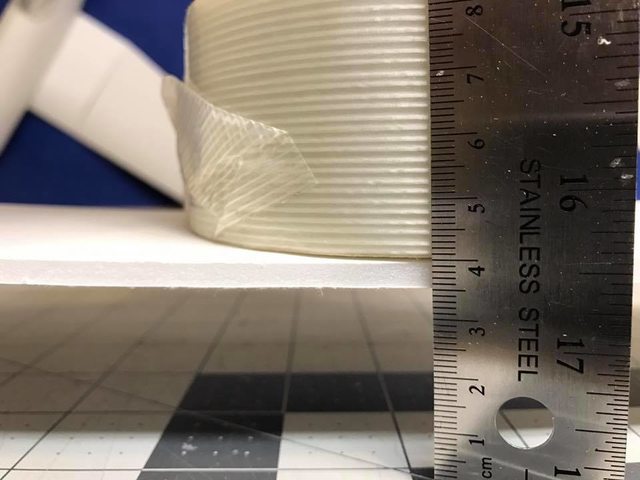

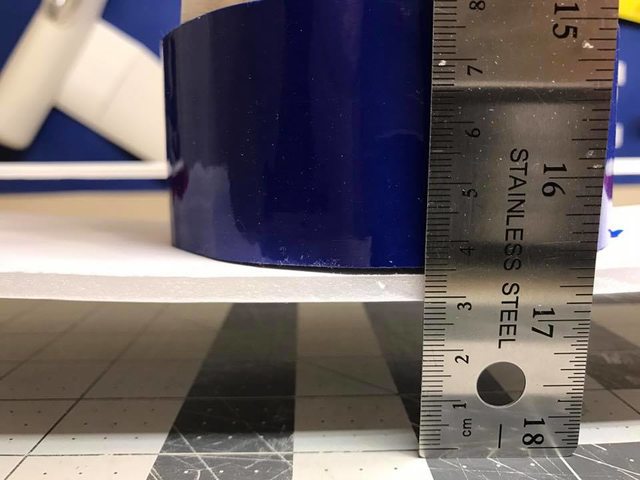

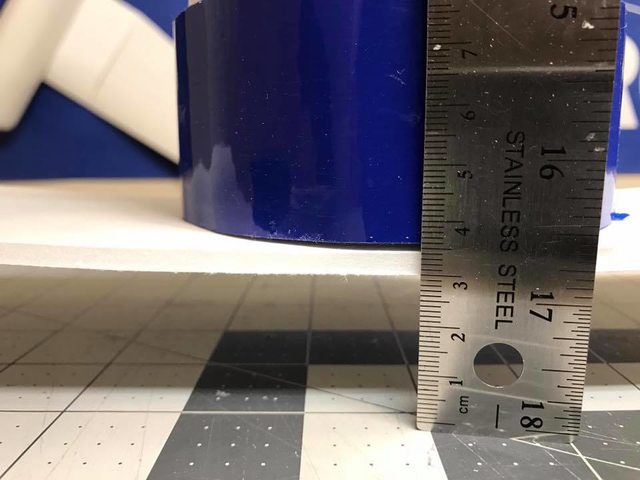

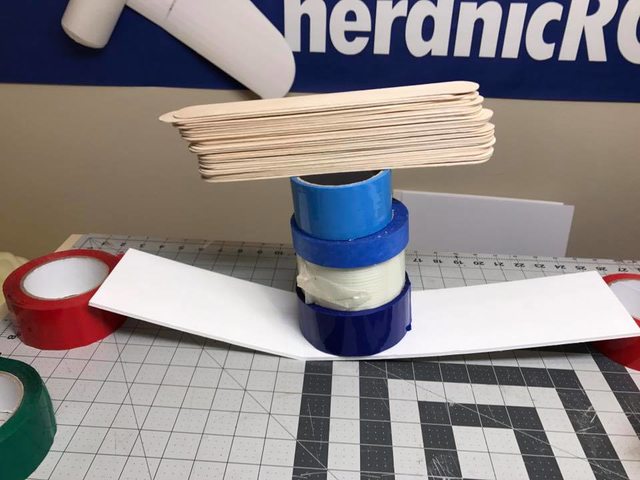

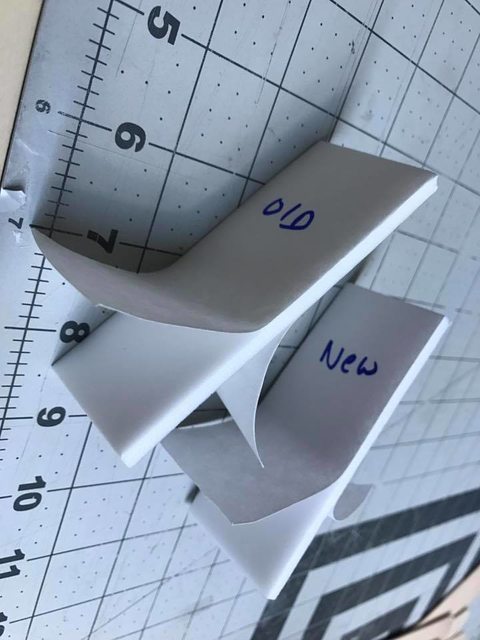

It looks like Adams has put out a new version of their standard board. It's being sold as a replacement product and has a new SKU: OLD 30525 NEW 30524 http://www.goadams.com/products/readi-board-foam-board/ The NEW version is bright white and has a different texture. From the 3 boxes worth I saw in the store, the boards seem to be more consistent in their flatness. I didn't really see any that were warped like the OLD board is sometimes. The NEW board feels a little more 'spongy' in your hand, I'm not sure how to measure this but it's noticeable. SHEET WEIGHT Original = 112g New = 115g TESTING I will be using rolls of tape of various weights and large popsicle sticks at 8g each. To keep this from being too large of a post, all weights were verified off camera on a digital scale. TEST 1 - Failure test on width cut

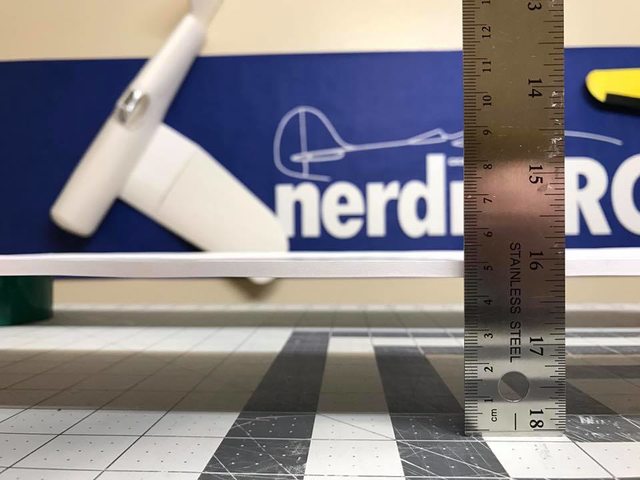

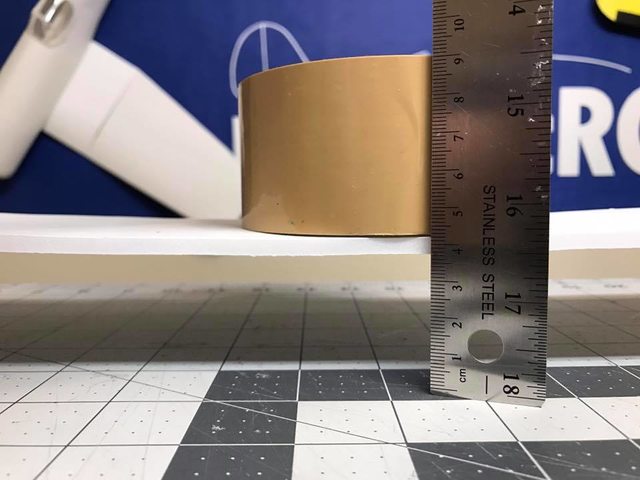

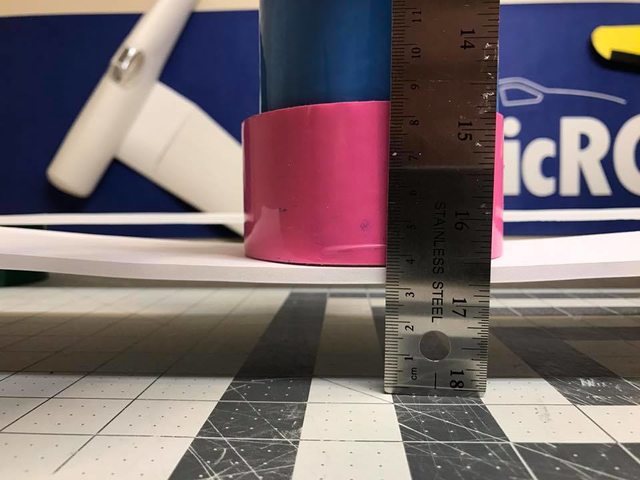

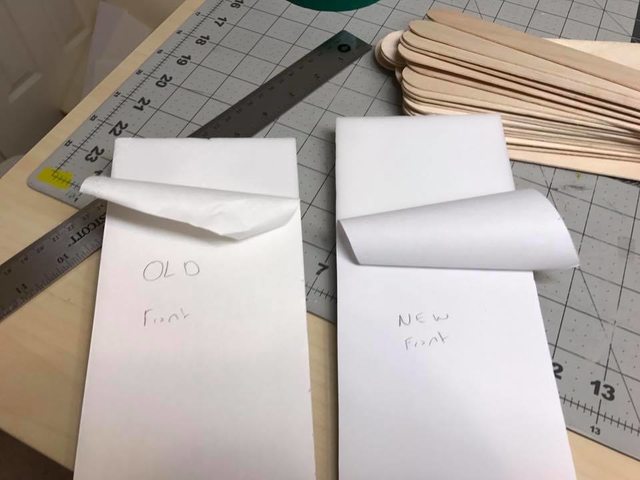

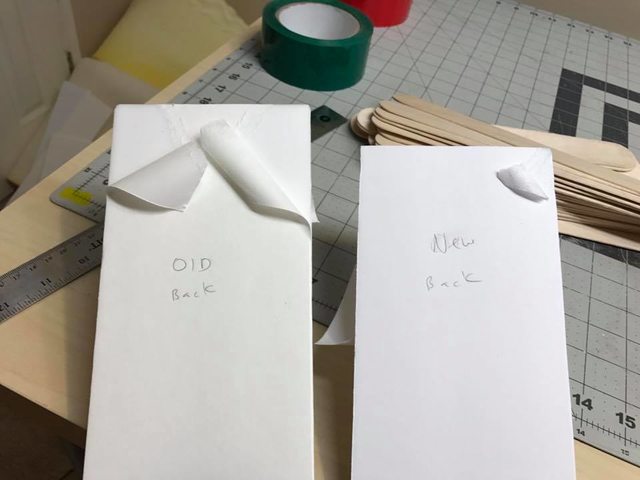

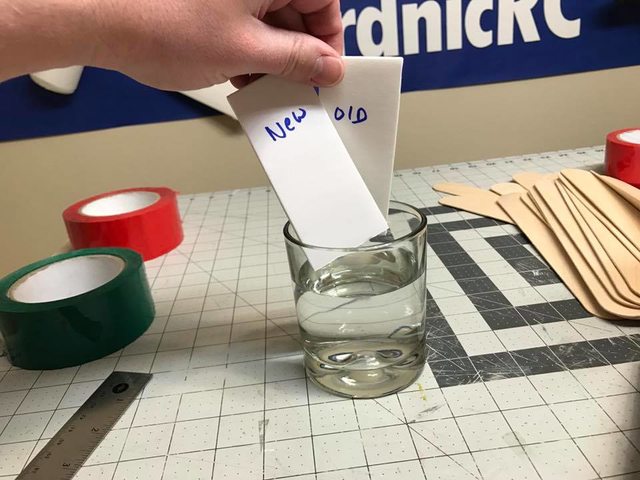

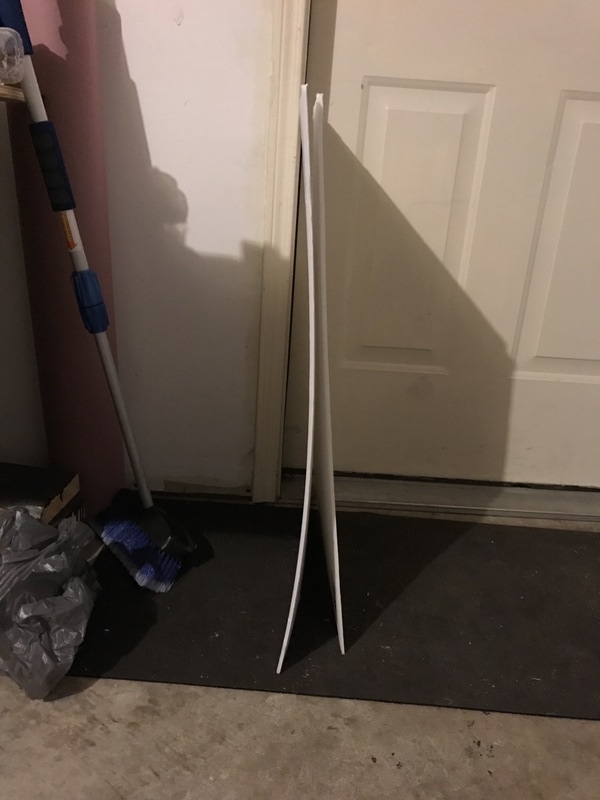

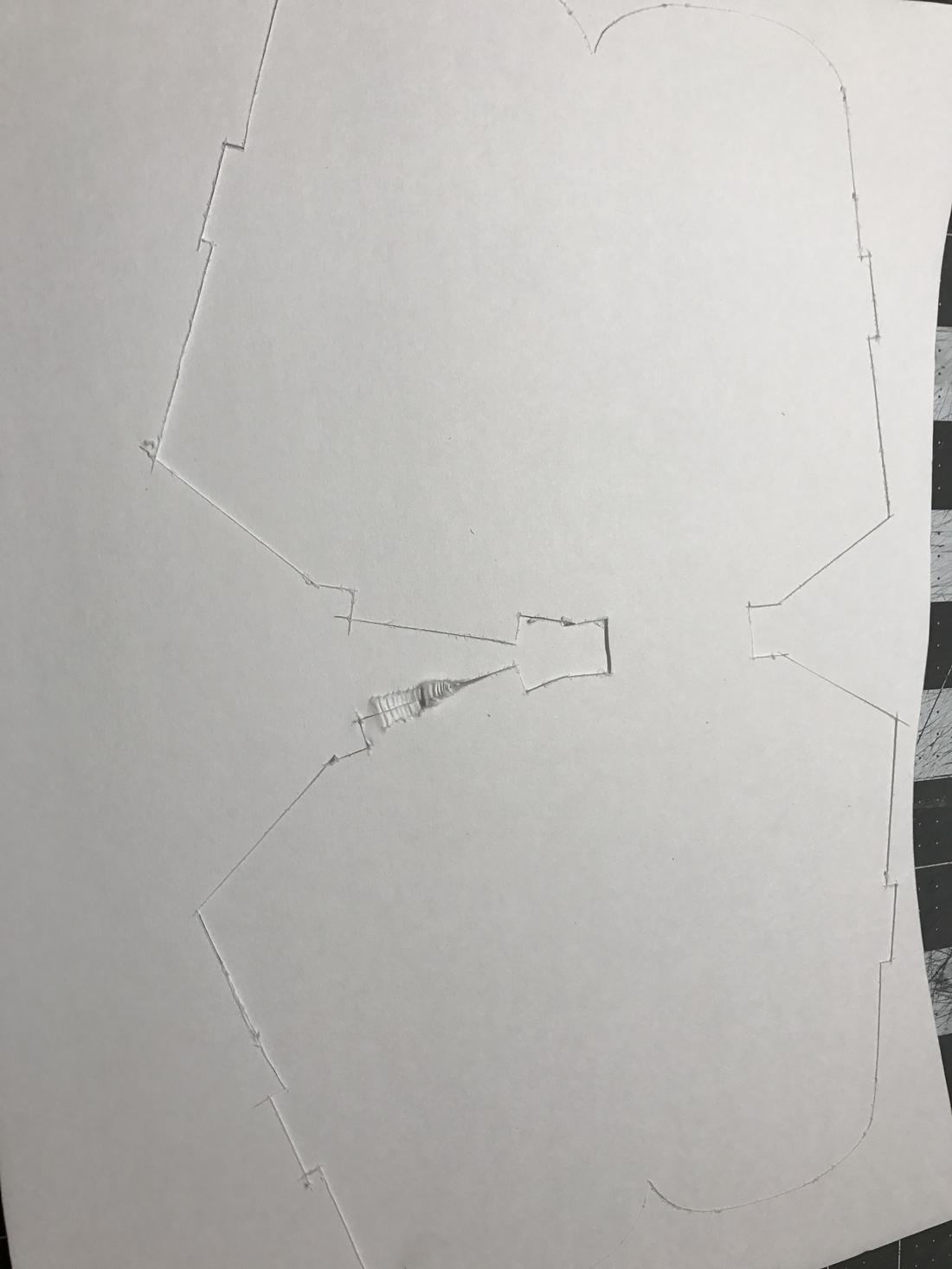

144 gram loadNEW foam deflected 1cm and the OLD .9cm. 200 gram loadNEW foam deflected 1.5cm and the OLD 1.3cm. 220 gram loadNEW foam deflected 1.55 and the OLD 1.4cm. 270 gram loadNEW foam deflected 1.9cm and the OLD 1.65cm. 300 gram loadNew foam deflected 2.05cm and the OLD 1.8cm. 460 gram loadThe NEW board produced a bent board that deflected all the way to the table without immediate failure. By the time I was able to grab a picture it had failed completely. With the NEW foam failed I will continue to find the OLD foams failure point. 508 gram loadOLD foam held 500g and then failed at 508g. TEST 2 - Failure test on length cutI am now going to do the same test but from the length of the board, I'll start at 400g. No load control is 4.6cm as before. 400 gram loadSimilar results but as you can see length cut is WAY stronger than width. I always keep this in mind for my builds, wings, stabs and fuse should ALWAYS run length wise. 600 gram loadAgain, similar results. The NEW foam is holding up better with the length cut. 800 gram loadThe NEW foam held up decent in the length cut test. TEST 3 - Paper removalGrabbing the corner and peeling back produced the same results on one side of the NEW board. It looks like one side of the NEW board has better adhesion though. This was consistent with 5 other boards I bought from the same batch. To my understanding Adams doesn't use an adhesive on these boards. The paper is rolled/pressed onto the foam while it's still hot. Because of this lack of adhesive, Adams board suffers greatly from moisture exposure. Will this be the same for the NEW board? TEST 4 - WaterTEST 5 - HumidityTEST 6 - BuildingI replace my blades with a fresh one often and have never had this level of blade snag before. Even when taking my time the cuts I produce on this new board look like I'm rushing through. If you get any glue on the paper it's nearly impossible to clean it off without ripping up the paper pretty bad. I think overall the new foam will still work but it's not as enjoyable to build with and the finished product won't look as clean. I'm pretty bummed out that Adams has taken this direction. I know our hobby is a drop in the bucket to their customer base but this new product is sub optimal. Test 7 - Brittleness

5 Comments

yes i had the same problem, and bought 20 per cut sheets 11x14inch to save me time cutting for my builds.. now after 2 try's i had the same thing with alcohol - old easy peeled off whole sheet if you spray and reapply while your doing it-wear gloves of your hands turn white dried out. ha

Reply

Edward Kipp

12/16/2017 12:01:13 am

I've been using the ross board from Walmart lately, my latest build with it is a simple scout that I painted as the paint adds considerable strength and moisture resistance. I'm going to talk to a manager and order a couple cases of it before they go changing it. The paper adheres better than DTFB, and it takes well to using a monokote iron to round the edges. I use both as they both have their own advantages...

Reply

Scott

1/20/2023 02:08:12 am

Never ceases to amaze me companies always cutting corners of the Save A Buck increase their profits and we're always the one that pays the price for a cheaper quality product.

Reply

Leave a Reply. |

© 2020 nerdnicRC