|

If you're like me then you know that plywood firewalls just don't hold up. After a few crash.. I mean hard landings, your motor will either break the plywood or the screws holding it in place will simply let go. This leaves you with an early trip home from the field. Over the years I have tried a bunch of different materials in search of the best firewall. In my eyes the best firewall would have all these qualities:

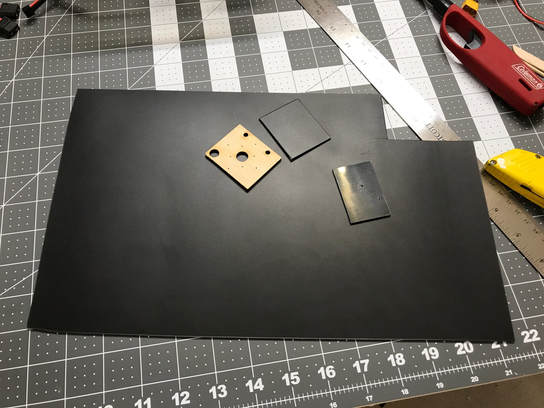

ABS is readily available so that's a huge plus. The challenge was finding the right thickness material in a cheap and commonly available product. If you can locate the correct material AND find a cheap product to salvage the material from.. that right there is a DIYers dream. So head to Walmart, Target, Home Depo, Lowes, or whatever super store you have in your area and grab a simple wastebasket. This one cost only a few dollars and you can make more firewalls than you'll ever need. https://www.lowes.com/pd/Style-Selections-7-Gallon-Black-Plastic-Touchless-Trash-Can/3052353 With an 18" metal ruler and a utility knife cut out one side. It only takes 4-5 passes with the blade to cut through. Take a reference firewall and trace it out. Another 4-5 swipes of your blade and you should have perfect cut firewall. Because the material is relatively soft it is really easy to work with. If you're using screws to mount your motor that will self tap then you don't even need to drill reference holes. Screws will thread right into the plastic, just don't tighten past snug. It's thinner than a ply firewall too, and much more durable. For just a few dollars you can make a lifetime supply of airplane firewalls. They are easy to cut and don't require any special tools. They will also hold up to the most extreme abuse. I have used these on my Sonic Series (650mm) planes all the way up to 1500mm warbirds with massive motors. Happy building :-)

3 Comments

MostlyGeniusRC

7/23/2017 09:39:53 am

Nice. I just use thicker plywood, and I haven't had a single break. :)

Reply

Leave a Reply. |

© 2020 nerdnicRC